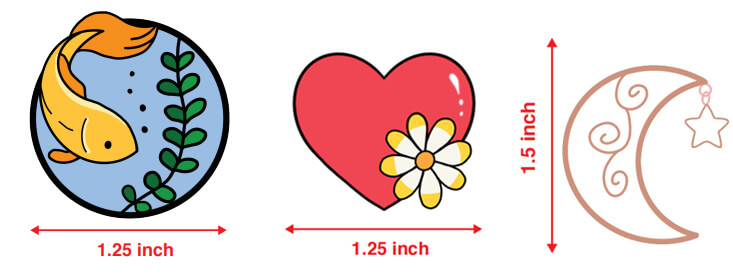

This is a hard enamel pin inquiry from an American illustrator. The designer is very proficient in graphic design, her designs are mainly inspired by the lover of nature. She found us through Instagram and wanted to talk with us about completing a project of 3 hard enamel pin badges. The vector files and specific parameters were given in the email:

50 pcs each design, hard enamel pin raised back stamp, gold/rose gold plating, screen print one color. Would like to know about the price, production process, and production time.

1. Hard Enamel Pin Solution Recommendation

The customer marked the specific Pantone colors very clearly in the vector file, and the instructions were also very organized. Through this customer’s INS, I learned that this was not the first time for the customer to make enamel pins, so she had some experience. Therefore, we must show our quality and service advantages to reassure her.

After receiving the email with the designs, we responded within 1 hour and gave relevant suggestions:

- Using iron material, the cost is low, and it does not affect the quality of the finished product;

- With the same back stamps, the iron material can share the mold, saving the cost of 2 molds;

- The third design is the moonlight + starlight design. We recommend adding an extra layer of glow-in-the-dark effect to make the product more attractive.

- All colors and shapes of rubber posts are shown to the customer so that she can freely choose to match the designs.

She expressed that she liked our efficient and constructive communication very much, and she hit it off with our ideas. Details such as price, delivery date, and payment method were confirmed then, and it took less than 24 hours from the inquiry to order confirmation.

(Another related client case: Custom Combination Pin Badge for USA Client)

2. The Cooperation Process

The customer is concerned about the production progress. We understood it very well and took the initiative to take production photos for the customer so that she knew where her products were. Regarding the glow in the glow-in-the-dark, we specially took one to try out and sent it to her to see the effect. She appreciated our work attitude and professionalism.

(Another related client case: Fantasy Pin Project from USA)

3. Custom Hard Enamel Pin Production Process

The production simply includes 4 processes, mold engraving, stamping, enamel filling & plating, and quality inspection.

(Another related product guide: A FAQ Guide for Manufacturing and Selling of Enamel Pins )

4. Custom Hard Enamel Pin FAQs

Q: What’s your MOQ?

A: No MOQ, no matter how many pieces you need, they all deserve our best sincere service.

Q: How fast is your turnaround time once the production artwork proof is approved?

A: About 12-15 days for normal enamel pins. It finally depends on how complex the design is.

Q: Do you do different colored rubber pinbacks?

A: Different colored and shaped rubber pinbacks can be provided for your selection.

Q: What special enamel processes do you offer?

A: More than 200 kinds of glitter can be added to enamel colors. Screen printing, UV printing, glow-in-the-dark, transparent color, pearlescent effect, and stained glass effect can be combined with hard enamel.

Q: Do you do a thorough quality inspection on every hard enamel pin order I place?

A: We will conduct a full inspection of each process, and repair it immediately if any defects are found. Before shipment, professional QC will also inspect strictly to ensure that the finished products sent to customers fully meet the quality standards.

(All the FAQs About SICpin Products: SICpin Product FAQs )

5. Our Customer Feedback

After the customer received the package, she was very pleasantly surprised by the real quality and turnaround and said that she would enter into a long-term cooperation. From the first cooperation in 2020 to now, we have become close partners.

(Another related client case: Swimming Medal Events from the UK)

6. Summary

Why can we be favored by customers and achieve long-term cooperation?

- We have a skilled and professional service team. From business communication, order production, and express delivery, timely communication and rapid response can be achieved.

- We have complete archives and records of each customer’s needs, working habits, and priorities, so targeted services can be provided.

- Many years of experience in metal crafts production help customers choose the most reasonable material, plating, and processes, and help reduce customer costs while ensuring quality.

- In terms of quality, we have always been adhering to the meticulous craftsman spirit. At each product step, a full inspection has to be done to ensure high-quality finished products before leaving our factory.

As an experienced hard enamel pin manufacturer, whether it is hardware equipment, service concept, staffing, or quick response, we are very confident in providing customers with a full range of services, that greatly exceed customer expectations.

SICpin has a workshop area of 2300 square meters, 42 employees, and 26 sets of production equipment. We always maintain technological innovation in the enamel pin manufacturing industry and guarantee product quality with advanced equipment and strict management concepts.

At least 500,000 pins are produced monthly, involving corporate groups, political events, sports, fashion culture, product accessories, art design, and other fields. We maintain in-depth cooperation with customers in more than 40 countries and regions.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 5

No votes so far! Be the first to rate this post.