Custom Enamel Pin Manufacturer From China

Free quote & design, experience team, enthusiastic sevice

12 different enamel pin crafts, more than 8 million pins are produced annually, praise from over 3,000 customers

SICpin Custom Enamel Pin

The enamel pins include soft enamel pins and hard enamel pins. No matter which enamel type you select, they can perfectly combine unique designs with vivid colors, giving people a bright feeling!

SICpin customizes enamel badges according to your ideas or designs. Screen print, UV print, glow in the dark, transparent color, pearlescent effect, stained glass effect and other color effects can be done to meet your pin requirements. Certainly, rotation / dynamic spin, pin on pin, print and other multi-style badges can also be customized here.

Sicpin can produce enamel pin for 700,000 pcs month. In the past 5 years, our customer satisfaction rate has reached 98.8%, and it has been rising year by year.

Your inquiry will be replied in 24 hours

Custom Enamel Pin Examples

Head Portrait Pin

- Technology: 2D

- Material: zinc alloy

- Size: 1.5 inches

- Color: soft enamel

- Plating: dyed black

Martian Pin

- Technology: 2D

- Material: zinc alloy

- Size: 2 inches

- Color: soft enamel

- Plating: black nickel

Fly Pin

- Technology: 2D

- Material: zinc alloy

- Size: 2 inches

- Color: soft enamel

- Plating: rainbow

Bee Pin

- Technology: 2D

- Material: iron

- Size: 1.75 inches

- Color: soft enamel with glitter & epoxy

- Plating: dyed black

Koopa Troopas Pin

- Technology: 2D

- Material: zinc alloy

- Size: 1.5 inches

- Color: hard enamel

- Plating: black nickel

Hera Pin

- Technology: 2D

- Material: zinc alloy

- Size: 2 inches

- Color: hard enamel

- Plating: black nickel

Pomeranian Pin

- Technology: 2D

- Material: brass

- Size: 1.25 inches

- Color: hard enamel with printing

- Plating: rose gold

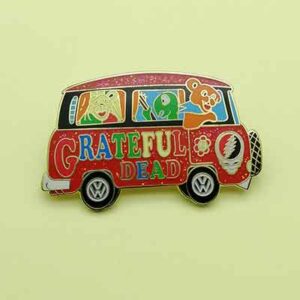

Grateful dead Pin

- Technology: 2D

- Material: zinc alloy

- Size: 2.5 inches

- Color: hard enamel with glitter

- Plating: gold

Customize Enamel Pin For Your Projects

We can provide customized service according to customers’ drawings or ideas.

Your inquiry will be replied in 24 hours

SICpin Enamel Pin Features

- Provide design assistance for free, respect originality and crack down on theft

- A variety of metal plating options, colors dyed and anodizing for your choice

- Glitter, glow in the dark, screen print, etc…Many color effect can be done on lapel pin

- There are butterfly clutch, rubber post, magnet, luxury cap and other accessories

Call Us

+86-147 1498 0815

Our Email

info@sicpin.com

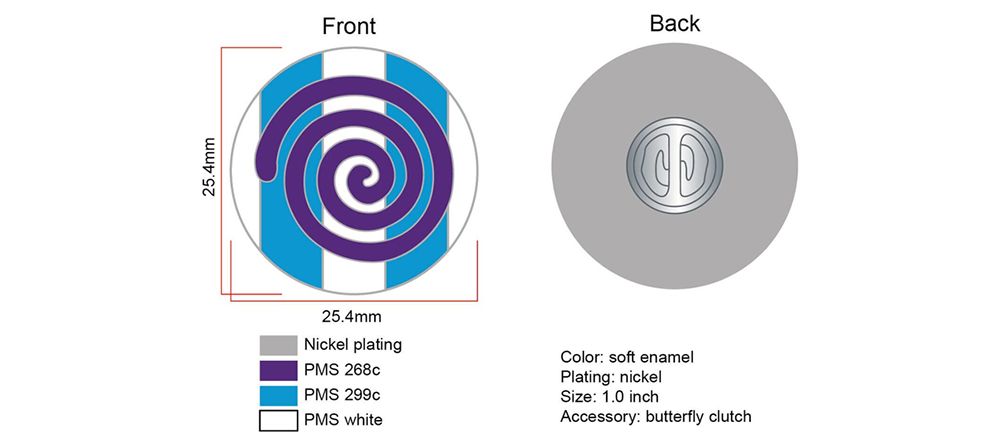

Custom Enamel Pin Specification

- Design assistant: We can provide free design assistance based on your drafts or ideas.

- Production experience: We provide different options for your design according to our practical production experience

- Property copyright: Any idea is priceless, and you will own the copyright to the art.

- Respect original: We respect originality and are committed to crack down on theft.

- Iron: Lowest unit price, not suitable for designs with many cutouts

- Brass: Higher end and more expensive, no many cutouts on it.

- Zinc alloy: The price is moderate. Suitable for almost any metal design.

- Glitter: More than 200 kinds of glitter can be added to enamel color

- Special enamel: glow in the dark, transparent color, pearlescent effect, stained glass effect…

- Screen printing: Screen printing is the perfect solution for small details that can’t be displayed on enamel. The screen printing costs $80 per color.

- UV printing: UV printing can show more complex colors and details. More expensive, and more complex to produce

- Butterfly clutch: The butterfly clutch is metallic and blends in with the lapel pin.

- Rubber post: There are many colors of rubber posts for you to choose from. The most common ones are black, yellow, and pink.

- Magnet: The magnet accessories can protect the clothing from damage in the process of wearing the lapel pin. It’s very prevalent in the Middle East.

Steps to Custom Enamel Pins

Designing

We can provide free design assistance based on your ideas.

Quotation

Free quotation according to quantity, size, coloring, plating etc.

Production

Updated production photos will be provided from time to time

Shipping

Shipping by FedEx after strict quality inspection & protective packaging.

Custom Enamel Pin Manufacturer FAQs

No MOQ, no matter how many peices you need, they all deserve our best sincere service.

Support. Many customers do not have enough confidence in the quality made by new factories. In order to better demonstrate our excellent quality to customers, we support mold making and proofing and then proceed to mass production after getting the customer’s green light.

Size, plating, enamel type, quantity. Or if you have no idea, we will advise.

We have an experienced design team who focus on the graphic design of metal crafts. We can help with drawing the sketches as long as you tell us the ideas.

We support rush orders. We usually handle urgent orders by working overtime, adding people, adding machines, etc., and will meet customers’ schedules.

We will conduct a full inspection of each process, and repair it immediately if any defects are found. Before shipment, professional QC will also inspect strictly to ensure that the finished products sent to customers fully meet the quality standards.

Are You Looking for Custom Enamel Pin Manufacturers?

Contact us for design assistance, free quote, and professional advice today.

We will provide you with a free quote within 24 hours, and we respect your privacy.

If you are looking for some enamel pin suppliers, and need custom enamel pins at the most competitive prices, this guide will help you.

Enamel pins are promotional items used by companies to promote their brand, office, or products. Promotional items make great gifts for customers and employees.

Promotional items can be used as incentives rewards for meeting company goals, or as party favors. In addition to offering a wide range of products, enamel pin manufacturers must ensure their brands are effectively marketed. Enamel pin suppliers can be difficult to find. There are many things to keep in mind when choosing the right supplier for your project.

An enamel pin is a pin made of metal or ceramic. They are used in a variety of ways, but one of the most popular uses is as a collar pin. Brooches are often used to commemorate something of a person or organization. Enamel pins are usually attached to clothing with the back of the pin. Enamel pin making is a traditional craft that has been passed down in Europe for hundreds of years.

It was possible to reproduce hard enamel pins with precision and detail by enamel pin manufacturers. These hard enamel pins have become very common in the fashion industry because they offer more flexibility in creating custom designs that artists can customize and sell on their websites and through online platforms such as Etsy, eBay, and Amazon.

You will come across many different types of enamel pins on the market. Enamel pins are often given as a gift as a token of appreciation. Different shapes and sizes are available. A variety of enamel pins are made by enamel pin manufacturers, including hard enamel pins for dealers, decorative enamel pins for collectors or events, and novelty items such as alligator clips, spoons, and key chains.

Either hard enamel pins or soft enamel pins can be customized. Due to the harder material used in hard enamel pins, they are more durable than soft enamel pins. Due to their harder edges and sharp corners, they are more durable than soft enamel designs.

Hard Enamel Pins: Hard enamel pins are made of brass or steel and can be molded into a variety of different shapes. These pins usually have a clasp on the back to secure them to clothing.

Soft Enamel Pins: Soft enamel pins are usually shorter and thinner than hard enamel pins, and often have a rubber backing. They can be used on clothes and backpacks or other items that require connecting pins multiple times.

The pin design is very different from print or web design. We create a 3d piece of metal with your artwork printed on it, which is then plated and hand-painted. Many pin buyers are unaware of this process, and thus put a lot of design skills aside. Follow this Covid Hero Award pin through the lapel pin factory.

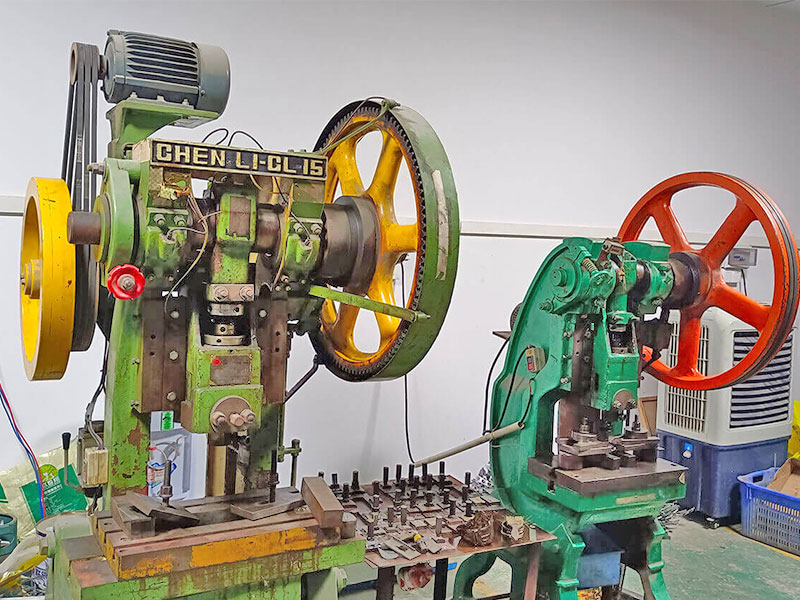

1) Mold Engraving

Most enamel pins are made using a molded manufacturing process. This process requires stamping dies in order to stamp your design into the zinc metal. In most cases, this process takes approximately 2-3 days to complete. Special industrial steel is used to make the mold. We use CNC manufacturing techniques to reverse engrave your design into steel.

This process is time-consuming, with most stamping dies taking about 10 hours to make. When you pay the setup fee, that’s what you pay for. This is also why 25pc orders often don’t work. The general logic is that fewer pins cost less, but that’s not the case for enamel pin manufacturing.

The factories don’t want your 25-piece order and will charge accordingly. After all, it takes as much time to set up a press to produce 50 as it does to produce 5,000.

2) Tools and Dies

A “tool and die” is required so that the pins can be trimmed after the design is stamped into the metal strip. The “tool” is the outline of your pin. To remove excess metal from the pin blank, a “die” is used. There is a lot of time spent on this part of the process. Remember, we haven’t even made pins yet!

3) Stamping

Now that the molds, tooling, and dies have been made, we can start manufacturing your pins. The machine operator adds your stamping dies to the hydraulic press. To give the metal the shape you designed, the operator applies approximately 5 tons of pressure to a strip of zinc metal on top of the mold.

4) Trim

Once your pins are stamped into the zinc strip, the project is transferred to the trimming press. The excess metal around the pin is cut away. Each pin is rough cut and then placed on a trim die. The “tool” is used to cut away the excess metal and give the pins a nice crisp edge. The “die” is the shape into which the pin is cut into the steel. Now we can start decorating your pins!

5) Electroplating

Electroplating is a very interesting process. This is part of the process by which metals are turned into gold, silver, and bronze. The enamel pin trend has led manufacturers to offer metal in other colors, such as black, blue, pink, or green. Instead of plating, they paint the metal with a color or a color of your choice. This makes it easier for designers to create black lines on their pieces without having to convert those lines to gold metal. The pins are attached to the metal frame by hand and connected to the frame with copper wire. This allows current to flow through the pins when placed in a series of chemical baths. Gold/nickel/bronze particles adhere to the needles, changing color according to the solution they are placed in.

6) Enamel

We finally get to the fun part! painting! Once your pins are plated to the correct color, the pins are loaded onto the rack for painting. The metal base is heated to make the colors flow better. Technicians use colored syringes filled with liquid epoxy to inject color into your pins. Each color is tessellated one at a time. Your pin design needs no smaller than a 2mm area to accommodate the liquid epoxy. Designers, that’s often why we have to change your art! We need enough room to accommodate the colors within any given enclosed metal shape. (Check out our Pin Designer cheat sheet which gives you a list of specifications and best practices to follow)

7) Polishing

There is an extra step if you order hard enamel. In the hard enamel process, we fill the pins with more paint. To give it the finished look we need to polish the surface until the paint is flush with the metal edges. This is one of the reasons why hard enamel costs more each pin is polished by hand. “The Difference Between Hard and Soft Enamel Pins” is another Medium article I wrote.

8) Organize

Once your pins are stamped, plated, and painted, they receive a finishing touch. Completion is divided into three parts:

- Solder the posts on the back. We attach a post to the back of your pin using a specialized spot welder.

- Each pin has a clutch added by hand on the back

- Plastic bags are used to package each pin

Now we’re ready to ship your pins! You will be an expert once you learn about manufacturing and enameled needle design best practices.