Custom Hard Enamel Pin with No MOQ

No MOQ, free artwork & quote, highest quality delivery

Glitter, screen print, UV print, glow in the dark, transparent color, pearlescent effect, and other color effects can be done

Hard Enamel Pin Manufacturer

Hard enamel pin, also called Cloisonné enamel pin, it has a jewelry-like appearance with a high perceived value. The hard enamel pin badges market is extremely active in commercial art fields such as animation, celebrity, and art collections.

SICpin will give professional advice on enamel color, size, accessory, plating, etc. Screen print, UV print, glow in the dark, transparent color, pearlescent effect, stained glass effect and other color effects can be done to match your pin requirements.

We serve more than 300 customers per month on average, covering more than 40 industries. The customer satisfaction rate has reached 98.8%, and it has been rising year by year.

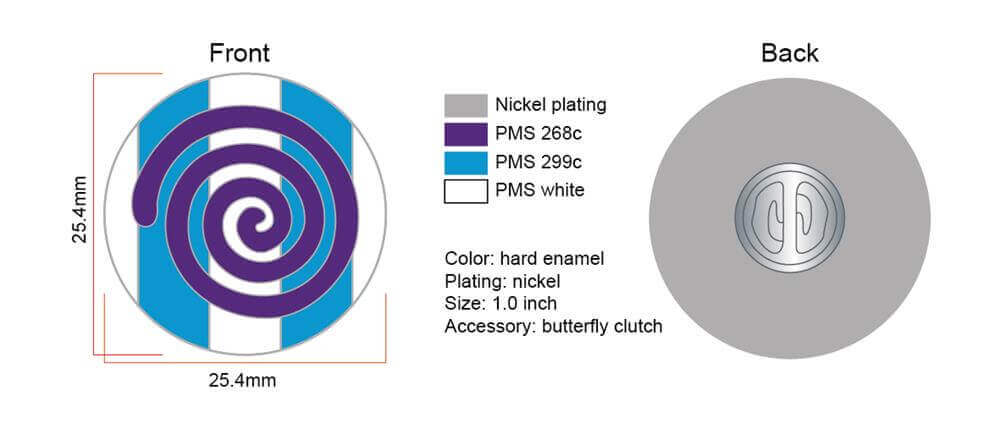

Featured Hard Enamel Pins Specification

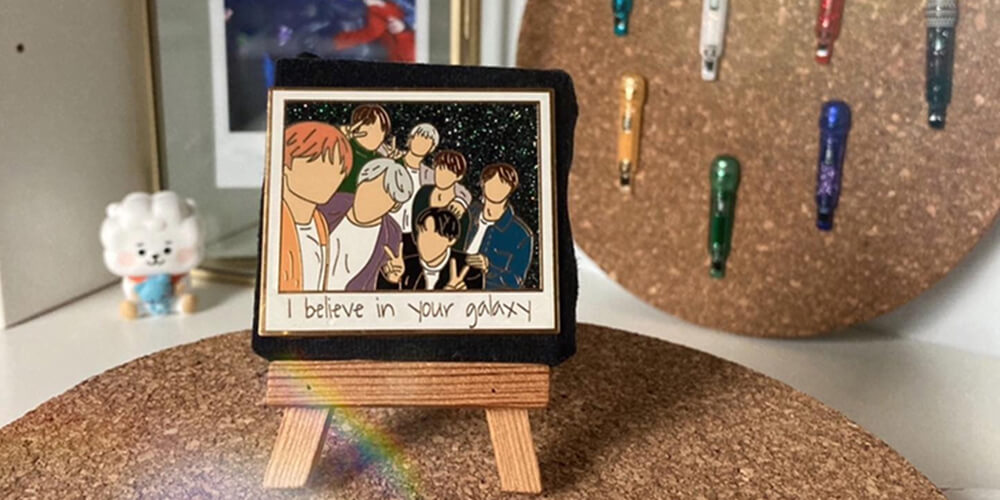

BTS Pin

- Technology: 2D

- Material: brass

- Size: 2 inches

- Color: hard enamel with glitter

- Plating: gold

Yoonmin Pin

- Technology: 2D

- Material: brass

- Size: 1.75 inches

- Color: hard enamel

- Plating: rose gold

Stitch Pin

- Technology: 2D

- Material: zinc alloy

- Size: 2 inches

- Color: hard enamel

- Plating: gold

Sailor Moon Pin

- Technology: 2D

- Material: brass

- Size: 2 inches

- Color: soft enamel with glitter & epoxy

- Plating: gold

Golden Retriever Pin

- Technology: 2D

- Material: brass

- Size: 1.75 inches

- Color: hard enamel

- Plating: gold

Witch Pin

- Technology: 2D

- Material: iron

- Size: 2.25 inches

- Color: soft enamel

- Plating: dyed black

Milky Tea Pin

- Technology: 2D

- Material: zinc alloy

- Size: 1.75 inches

- Color: hard enamel with glitter

- Plating: black nickel

Cute Bear Pin

- Technology: 2D

- Material: brass

- Size: 1 inch

- Color: hard enamel with screen printing

- Plating: gold

Customize Hard Enamel Pin

We can provide customized service according to customers’ drawings or ideas.

Custom Hard Enamel Pin Solution

- Provide design assistance for free, respect originality and crack down on theft

- Glitter, glow in the dark, etc…Many color effect can be done on soft enamel

- Small details such as eyelashes and patterns can be printed on hard enamel pins

- There are butterfly clutch, rubber post, magnet, luxury cap and other accessories

Call Us

+86-147 1498 0815

Our Email

info@sicpin.com

SICpin Hard Enamel Pin Specification

- Design assistant: We can provide free design assistance based on your drafts or ideas.

- Production experience: We provide different options for your design according to our practical production experience

- Property copyright: Any idea is priceless, and you will own the copyright to the art.

- Respect original: We respect originality and are committed to crack down on theft.

- Iron: Lowest unit price, not suitable for designs with many cutouts

- Brass: Higher end and more expensive, no many cutouts on it.

- Zinc alloy: The price is moderate. Suitable for almost any metal design.

- Glitter: More than 200 kinds of glitter can be added to enamel color

- Special enamel: glow in the dark, transparent color, pearlescent effect, stained glass effect…

- Screen printing: Screen printing is the perfect solution for small details that can’t be displayed on enamel.

- UV printing: UV printing can show more complex colors and details. More expensive, and more complex to produce

- Butterfly clutch: The butterfly clutch is metallic and blends in with the lapel pin.

- Rubber post: There are many colors of rubber posts for you to choose from. The most common ones are black, yellow, and pink.

- Magnet: The magnet accessories can protect the clothing from damage in the process of wearing the lapel pin. It’s very prevalent in the Middle East.

Steps to Custom Hard Enamel Pin from SICpin

Designing

We can provide free design assistance based on your ideas.

Quotation

Free quotation according to quantity, size, coloring, plating etc.

Production

Updated production photos will be provided from time to time

Shipping

Shipping by FedEx after strict quality inspection & protective packaging.

Hard Enamel Pin Manufacturer FAQ

No MOQ, no matter how many peices you need, they all deserve our best sincere service.

We can help with drawing the sketches as long as you tell us the ideas. Under fit-in-production conditions, we support unlimited revisions until the customers say good.

Butterfly clutch, rubber post, magnet, safety pin, luxury cap, etc… Each accessory has different specifications, welcome to consult.

More than 200 kinds of glitter can be added to enamel colors. And screen printing, UV printing, glow in the dark, transparent color, pearlescent effect, stained glass effect can be combined with hard enamel.

We will conduct a full inspection of each process, and repair it immediately if any defects are found. Before shipment, professional QC will also inspect strictly to ensure that the finished products sent to customers fully meet the quality standards.

A: For lightweight packages, we usually use FedEx, UPS, and DHL Express, 3-8 days of transit, which not only guarantees delivery time but also reduces a lot of troubles for customers by door-to-door express.

Custom Your Hard Enamel Pin from a Direct Manufacturer Now

Contact us for design assistance, free quote, and professional advice today.

We will provide you with a free quote within 24 hours, and we respect your privacy.

Hard enamel pin, also called Cloisonné. It’s an ancient metalworking technique for jewelry, vases, and other collectibles in ancient times. Each color needs to be hand-filled. It needs baking as long as each color is filled circularly till completing the whole pin design colors. Then polished to a smooth finish and plate your custom metal.

Hard enamel pins (also called cloisonné pins) are made by pouring enamel several times in a recess in the metal and heating it at a very high temperature. It is then polished smooth to ensure the enamel is at the same level as the metal edge.

Hard enamel pin with a smooth surface. They are made by punching the pattern onto the metal, filling it with enamel, heating it to harden it, and polishing it to make the surface smooth and durable. Just like the soft enamel pins, they have a metal separating ridge between each enamel color.

The hard enamel pin is smooth and flat. When the enamel is filled, it is filled over the metal lines. When all the colors are filled in, the entire face of the pin is smoothed out.

Because of this, painted metal and iridescent metal finishes are out of the question, as the finish would be destroyed during the grinding process. Hard enamel is generally more durable and scratch-resistant than soft enamel. Typically, hard enamel pins cost more than soft enamel pins, and in the end, the choice of hard and soft enamel pins is often a matter of personal preference.

Also known as “pole pins,” these enamel pins are a designer’s choice because they offer a smooth and glossy finish. The sheen on hard enamel pins is created by adding each color individually and allowing each color to bake on the enamel separately. Once all the colors have been added, the custom pins are polished to show a sheen.

Hard enamel pins are made of molded iron, brass, or zinc alloy metal, and enamel. The only difference between hard and soft enamel is the heat applied to the enamel. Hard enamel lapel pins are easy to care for. It’s as simple as wiping with a wet or dry cloth or handkerchief.

Like soft enamel style pins, hard enamel pins consist of a highly polished raised metal surface, while the recessed areas of the pins are filled with premium colored enamel. The enamel on the pins is filled to the very top, so after it has been kiln cured, the hard enamel is ground flush with the polished metal. This makes the pin shine unlike any other style of lapel pin

In the design, adding enamel dye over and over again elevates the enamel higher so that it is flush with the edge of the metal, creating a flat surface effect. It is then heated at very high temperatures to harden and cure the enamel.

Hard enamel pins are durable and have a high-quality appearance. The craft is a multi-step enameling process used to produce jewelry, vases, and other decorative items. For hard enamel, add enamel before plating. Add enamel powder and sand the tan stone flat to the same level as the metal mold line. Each color has to be baked one by one in the oven, which adds to the process and cost. Once all the colors are added the tan the badge can be plated and polished again to complete the badge. The extensive polishing process is why the badge achieves slightly less detail than soft enamel, and why some of the metal wires may have diffused in production and be thicker than the original design.

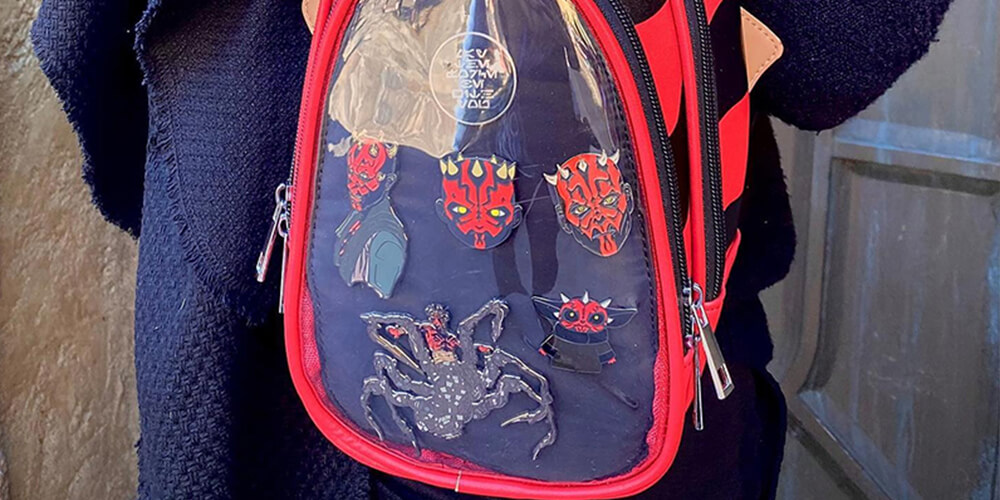

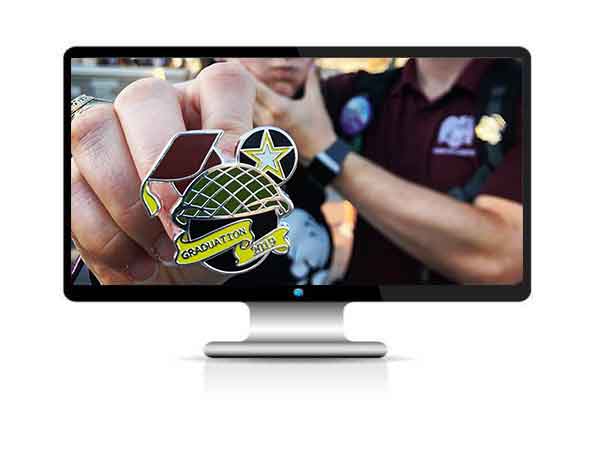

Enamel pins can be used for decorative purposes. They can also be used to denote a person’s association, cause, or organization. Enamel pins are often used as symbols of achievement. For example, businesses use enamel pins in their employee recognition programs, which are awarded to employees as a sign of their accomplishments and accomplishments. The organization distributes enamel pins to employees to improve employee engagement, productivity, and morale.

The first stage of designing an enamel pin involves forming the metal surface to create the design. In the second stage, a slicing mold is created. The next stage is the enamel color, which includes cleaning, toning, coloring, and baking before coloring. When each color is finished, it is baked at 90 degrees Celsius for 45 minutes, then the next color is applied, and the cycle continues until all the colors are finished. After the coloring process, the enamel should be polished to a smooth surface and cleaned again before electroplating.

1) Advantages of hard enamel pin

If you’re looking to make your own high-gloss pins, hard enamel may be the best custom option for your pin style. This type of pin achieves a smooth finish, so your custom final product won’t have the texture of a soft enamel pin. This flat surface makes this type of pin more durable than soft enamel, as the façade is less prone to scratches even when exposed to the elements.

If durability is important to you and you want to ensure that your custom pins will be able to make contact with hard surfaces, you should consider choosing a hard enamel. These enamel pins are protected with a high-gloss finish, so they can last longer without damage.

Even though these lapel pins are placed on tote bags, jackets, or other canvases to see a lot of movement and contact, it is rare for this type of pin to compromise.

2) Disadvantages of hard enamel pin

While these custom-made pins are durable and long-lasting, they still have some drawbacks that you should consider when choosing a style for your next custom project. First, keep in mind that hard enamel pins are completely flat and smooth. Therefore, if you want a rugged and textured pin, the hard enamel pin might not be the best choice for you.

The process of making these enamel pins is tedious and time-consuming, so the price of these pins is also slightly higher. If you want to make your own pins but don’t have a budget and aren’t worried about durability, you might consider using soft enamel pins instead.

It’s also important to remember that the process of making hard enamel pins can result in less vivid or vibrant colors. The color integrity of this style is less vibrant, so if you opt for hard enamel, your lapel pins may have a more muted hue.

Hard enamel pins are the more expensive of the two types of enamel. Hard enamel pins have a smoother surface. If you are looking to make an intricate design, then hard enamel is the right choice. They are much better at retaining color and precise detail than their softer counterparts. Likewise, the more you buy, the less you end up paying. Here is a price for a hard enamel pin for reference:

Size: 1 inch

Shape: round

Quantity: 100 pcs

Colors: 2 colors

Plating: gold

Accessories: rubber post

Mold fee: $40.0 USD

Unit price: $0.8 USD

Hard enamel pins are popular among professional organizations, sororities, and fraternities. They’re hand-painted and polished to remove any rough edges, so it’s no surprise that they’re more expensive and take more time to create. Because the lines in each design are raised slightly to distinguish the different colors. The pins are then sealed with a glossy protective layer and baked at high temperatures to produce a smooth surface with no indentations. On a hard enamel pin, the paint is level with the metal. To make a hard enamel pin, the factory makes a custom mold and fills it with dye material. pins are usually nickel, bronze or gold plated.

This is one of the most frequently asked questions, and the answer is fairly simple. In short, soft enamel pins have a textured/ridged feel when you run your finger over them, compared to hard enamel pins which have a smooth, flat surface. The biggest difference between hard enamel and soft enamel is the texture of the finished product.

When it comes to price, soft enamel pins are more affordable than hard enamel pins. This is because soft enamel pins don’t take nearly as much time as hard enamel pins.

Because the production process of hard enamel pins is more labor-intensive, manufacturers must pass on some of the production costs to consumers. It’s you! So if you’re on a really tight budget, you’re better off opting for soft enamel pins so you can save a few bucks.

Although hard enamel pins are more expensive than soft enamel pins, both types are affordable. In fact, enamel pins are hard to beat in price compared to other types of marketing products.

For example, if you were to order 1,000 custom-printed t-shirts in multiple colors, your total cost would run into thousands of dollars. But if you were to order 1,000 custom, multi-colored hard enamel pins, you’d only have to spend a few hundred dollars, not thousands.

Both hard and soft enamel pins have many advantages. Custom enamel pins offer amazing opportunities for businesses of all types and sizes. They are beautiful, versatile, eye-catching, and affordable.

Everyone loves enamel pins and they come in all shapes and sizes. You can completely customize your enamel pins to make them come out exactly the way you want them to.

Soft enamel pins are versatile and cost-effective. They allow for more complex designs than hard enamels. For a high-quality look and feel, soft enamel pins are easier to produce, making them less expensive for consumers. However, these pins are not as durable as hard enamel pins.

Hard enamel pins will last for years. Although the price is slightly higher, the quality is good. They are polished, smooth, and have a bubbly finish. These pins will not lose their luster or color over time. Hard enamel pins do take longer to produce and are therefore more expensive due to the several rounds of coloring required in the complex painting process.

The biggest difference between hard and soft enamel is the texture of the finished product. Hard enamel pins are flat and smooth, soft enamel pins have raised metal edges. Both methods use the same metal mold and both will have bright and vibrant colors. But they also have some special options, designed for soft enamels.

1) When to choose soft enamel?

Soft enamel is one of the most popular types of pins, with a raised and textured look and feel that many people love.

The enamel pins must be baked in the oven to cure and harden the enamel. Unlike hard enamel pins, the soft enamel metal plating process is done before the enamel is filled. This means they are metallic finishes that can only be used on soft enamels. If you want your pins to be rainbow plated, painted black, or any other custom color, tan, you’ll need to use soft enamel.

2) When to choose hard enamel?

Hard enamel pins are more durable and scratch resistant than soft enamel pins. Many people choose hard enamel over soft enamel because it looks clean. Many designs have both hard and soft enamels, so it’s mostly a matter of personal preference. First, fill the hard enamel pins with colors, and then smooth the surface of the pins. Grinding and polishing make them incompatible with some metallic finishes. If you want a standard gold or silver metallic finish, a hard enamel might be a good choice for your design.

A very important difference between hard and soft is that some metal finishes are only available with soft enamel. With soft enamel, your metal can be painted in any custom color you like. The most popular color is black. If you want black metal with hard enamel, your only option is black nickel. Black Nickel is actually a very dark gray color with a slight sheen. If your metal is real and deep black is important to your design, soft enamel is your best bet. Rainbow plating, also known as anodizing, is only suitable for soft enamels.

Hard enamel pins are premium. It has unique craftsmanship, it is hand sanded until the surface is shiny. The surface is delicate, and smooth like a gemstone, and the enamel is vivid, giving it a very noble feel and an affordable price. Widely used in company high-end pins, high-end commemorative pins, high-end collection pins, etc.

Also known as ebola pins, the new Cloisonné, Cloisonné II, Semi-Cloisonné, and Clois-Tech, hard enamel is not the new Cloisonné and has been around for over 20 years. They are designed by pouring enamel on the depressions of the metal before it is heated by high temperatures. They are sanded smooth to ensure they are level with the metal edges.

Hard enamel pins are usually the first choice and should be your first choice if you want a smooth and shiny enamel pin. Glow is created by the final polished pins creating a lustrous and jewelry-quality look and feel.

With that in mind, if you want high-gloss enamel pins, hard enamel is probably the best option. The smooth surface of hard enamel is the main difference from the textured surface of soft enamel. It has a smooth surface and is heated to high temperatures, making it one of the most durable enamel pins. This is because its front is not easily scratched or exposed to elements that could cause damage. So, if you want a durable enamel pin that can withstand a variety of hard surfaces and other elements, you might consider choosing hard enamel.

Just like soft enamel pins, hard enamel pins are textured to prevent color mixing. But instead of staying below the outline of the design, the color is constantly added to elevate the enamel so that it is level with the metal edge. This, front creates a flat finish that gives it a sleek look.

The process of making hard enamel is a bit complicated, but it’s definitely worth it. The surface is first filled with the desired enamel color and then baked or cured. The surface of the enamel pins is then lightly ground until it is smooth and flat. The non-combination of grinding and polishing makes hard enamel so recognizable.

However, you must keep in mind that hard enamel can be much more expensive than regular enamel pieces because they are time-consuming and labor-intensive. All in all, they’re a great option, especially if you want an enamel pin that will last for years. The quality speaks for itself and you can guarantee that it will not lose shape, shine, or color over time.