This custom medal inquiry was from a large beer club in USA, which holds on-site beer brewing competitions from time to time throughout the year. The person who contacted SICpin was the club’s competition coordinator. He was introduced by a friend and learned that SICpin has rich experience in medal design and manufacturing, so hoped to achieve long-term cooperation on custom medal projects. Separate medals will be for 1st, 2nd, and 3rd place at the event.

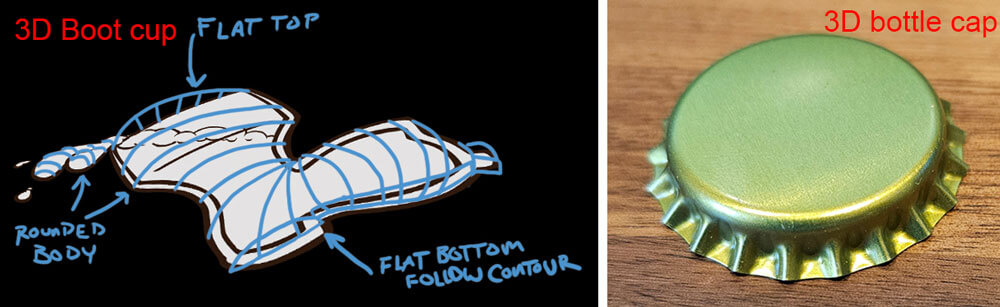

The customer who had experience in medal production provided a general design, detailed parameters and original drawings:

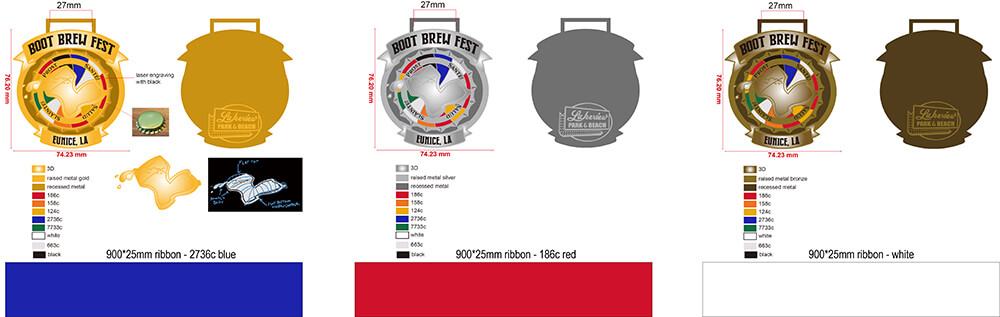

100 pcs, 3D medal, soft enamel colors, 3 plating, 3’’ size, backstamp, 3 colors ribbon versions.

1. Order details communication

In order to make the USA custom medal requirements more clearly, we recommended that they provide the medal design made from the last event. After comparison, the customer hoped the medal content to be more three-dimensional and rich through 3D effects.

To save their time and efficiently promote the medal project process, SICpin came up with the following issues:

- Can the 3D effect in the artwork be explained more appropriately with photos or hand drawings?

- Are the 3 types of plating gold, silver, and copper?

- What kind of sewing method and color did they prefer for the ribbon?

We confirmed all the details after getting a quick reply from the customer:

- 3D effect of bottle cap and boot wine glass;

- Shiny gold, silver and copper plating to distinguish 1st, 2nd, and 3rd place;

- The sewing method confirmed and the ribbons in three different colors of blue, red and white

After more in-depth communication, the customer hoped to use laser to process the text in the middle. Except for the adjustments on the enamel colors and ribbon colors many times, we also helped adjust other details such as size and position of the back stamp. After nearly a week of touch-up, gladly the USA customer was happy with the custom medal production artwork.

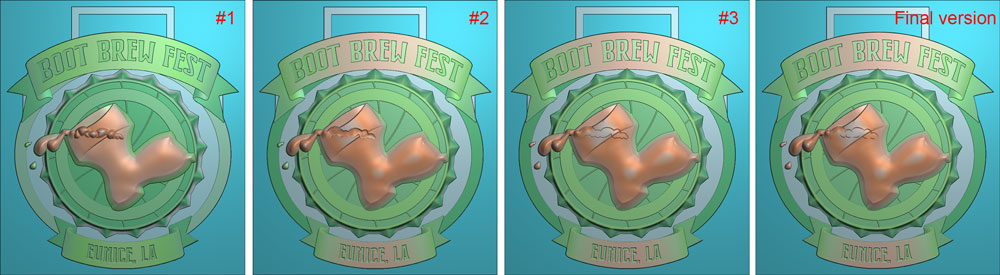

Although the digital artwork had been confirmed, in order to better show the 3D details, we drew CNC effect artwork for the customer to check and approve. Some small 3D details revised, then the order production was finally confirmed.

2. Production process

Because the early communication was very clear and all the details were in place, the USA custom medal production went very smoothly. He was also very excited to see the production updates we sent.

Finally, the medal trun out great! Whether it is color, 3D effect, plating texture or packing is very beautiful!

(Another related client case: Custom Medal Project From Spain)

3. Frequently Asked Questions During Cooperation

Q: What’s your MOQ for custom medal?

A: No MOQ, no matter how many pieces you need, they all deserve our best sincere service.

Q: How do you deal with urgent orders?

A: We support rush orders. We usually handle urgent orders by working overtime, adding people, adding machines, etc., and will meet customers’ schedule.

Q: What plating options do you have?

A: Gold, nickel, black nickel, silver, rose gold, antique, dyed, etc., are very widely used in hardware medals. For some competitive events, we suggest using gold, silver, and copper to distinguish the 1.2.3 rankings. Of course, antique finish is popular to pursue a retro style, such as antique gold, antique silver, antique copper, etc.

Q: Do you do a thorough quality inspection on every medal order I place?

A: We will conduct a full inspection of each process, and repair it immediately if any defects are found. Before shipment, professional QC will also inspect strictly to ensure that the finished products sent to customers fully meet the quality standards.

Q: What shipping methods do you support?

A: For lightweight packages, we usually use FedEx, UPS, and DHL Express, 3-8 days of transit, which not only guarantees delivery time but also reduces a lot of troubles for customers by door-to-door express. In some countries and regions, we also support door-to-door, double-clearance, and tax-free express delivery. If enough time is reserved for the event, we also support sea shipping for heavier medal cargo to reduce the customer’s budget.

4. The Customer Feedback

The customer was very satisfied with the medal quality after seeing them. Because of our outstanding service in the USA custom medal project, we are already preparing for preliminary consultation for the next order.

5. Summary

Through the case of the USA custom medal, why can we be favored by customers and reach long-term cooperation?

- No matter how big or small your order is, we treat it equally. We have enough patience with customers, constantly listen to needs, collaborate and implement actions, aiming to provide the best one-stop service for medal manufacturing;

- In terms of design, we are able to extract the information from the limited content provided by customers, and provide the most reasonable solutions in a timely manner for them to select;

- The cooperation of the whole production line is highly efficient and not dragged. From artwork details to items finished, our colleagues coordinate very well;

- Always think about problems from the customers’ perspective, and use the most appropriate technique way to help customers solve detailed problems before they ask questions.

- In terms of quality, we have always been adhering to the meticulous craftsman spirit. At each product step, full inspection has to be done to ensure high-quality finished products before leaving our factory.

As an experienced medal manufacturer, whether it is hardware equipment, service concept, staffing, or quick response, we are very confident in providing customers with a full range of services, that greatly exceed customer expectations.

SICpin has a workshop area of 2300 square meters, 42 employees, and 26 sets of production equipment. We always maintain technological innovation in the metal manufacturing industry and guarantee product quality with advanced equipment and strict management concepts.

At least 30,000 medals are produced and exported per month, involving marathons, Ball games, Dance, Martial arts, Bodybuilding, Swimming, and other fields. We maintain in-depth cooperation with customers in more than 40 countries and regions.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 2

No votes so far! Be the first to rate this post.